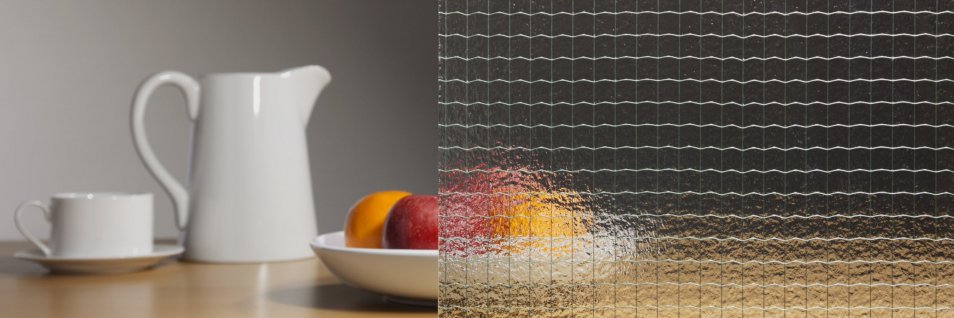

Coloured Laminated Glass offers all the benefits of a common laminated glass, such as increased security and UV protection, but in a range of vivid colors. These can be used individually, or they can be combined to offer a huge choice of different color options.

Colourer Laminated Glasses feature a big range of colors that can be used individually, or combined to offer a huge choice of transparent, translucent or opaque color options.

They are ideal for both decorative and commercial applications, including windows, walls, stairs, retail displays and railings.