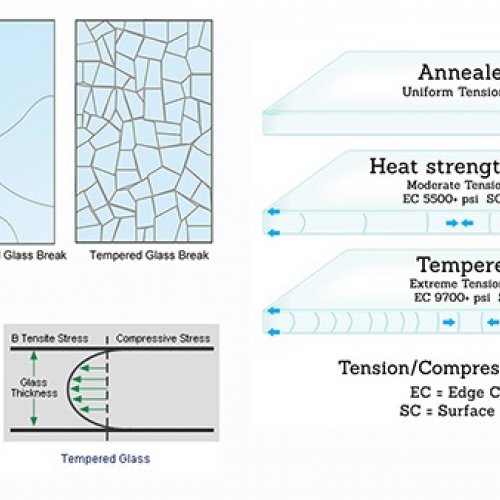

Heat-Strengthened Glasses have 2 times increased mechanical strength, compared to the corresponding thickness of common glasses. In case the breaking limit is exceeded, then they break into large pieces with the result that the pieces are held in place. They also show greater resistance to temperature changes (up to 200°C), which makes them invulnerable to heat shock (from non-artificial means).

Heat-Strengthened Glasses have approximately (but not the same) properties as tempered glasses (securit):

- They show 2 times increased mechanical strength, in relation to the same thickness of ordinary glass.

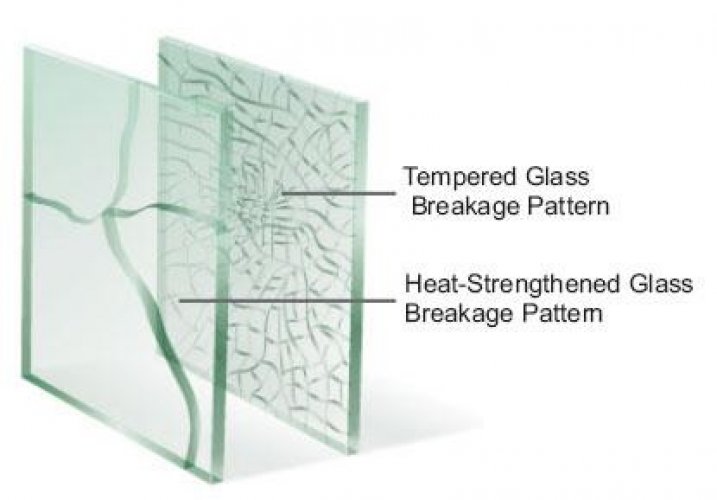

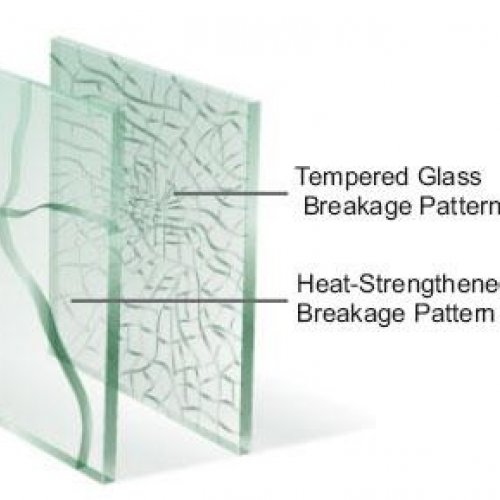

- In case the breaking limit is exceeded, then they break into large pieces which most often end up in the perimeter where there is usually adhesive material with the result that the pieces are held in place.

- They do not have a safety rating (they are not considered safety glass)

- They are clearly more resistant to temperature changes (up to 200°C), which makes them invulnerable to heat shock (from non-artificial means).

Heat-Strengthened Glasses Applications

Heat-Strengthened glass, unlike tempered glass (securit), has no safety rating and so their applications are more limited.

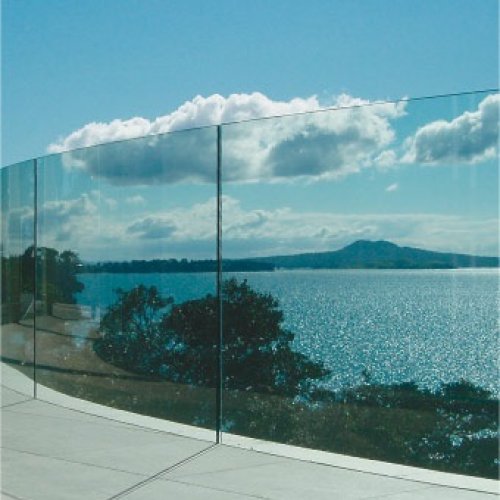

The most common application is in glass curtains of very high buildings when there are no balconies. This happens for 2 reasons:

- It has increased mechanical strength and breaks much harder than ordinary glass either by impact or heat shock.

- In case of breakage, the breakage pattern ensures that the pieces remain in place held in place by the perimeter sealing adhesive.

A second important application is on railings and balconies when there is no support frame. In these cases the safest solution is to use a laminated glazing consisting of 2 panes one of which is Heat-Strengthened and the other Securit. This is because in the event of a break, the breaking pattern of the Heat-Strengthened glass will prevent the overall glass from folding, giving the person in time time to move away to a safe location.